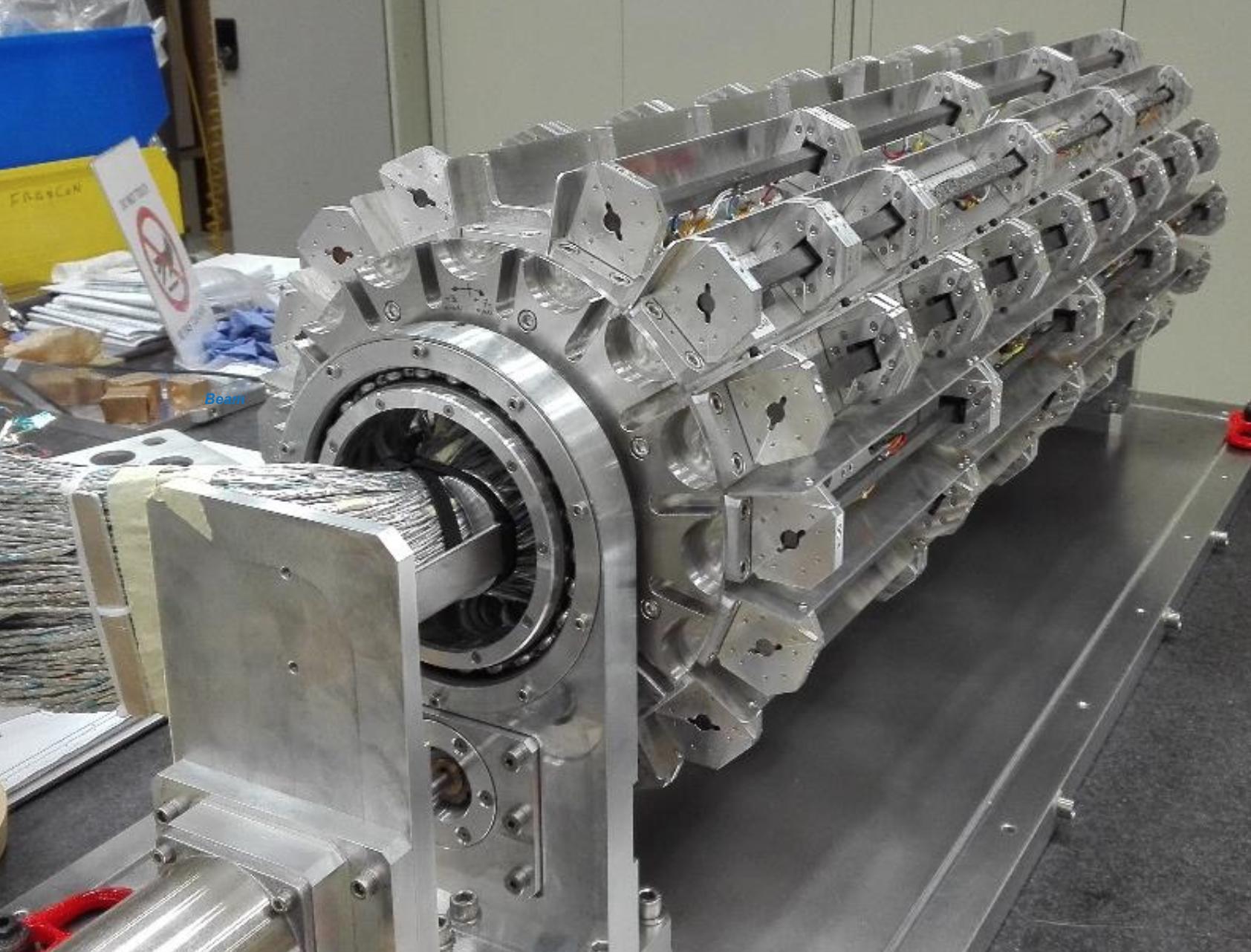

Detail of the collimator jaw that has three stripes of different resistivity values. The buld is made of a new material: molybdenum-graphite (MoGr). On the inner stripe, the MoGr is left uncoated. The yellow strip is made of TiN and the light-gray one of pure Mo. The tapering is also made of MoGr that is reuired because it has an eectrical resistivity that is low enough to allow the Beam position monitor (BPM, light-gray circle in the middle of the tapering) to work.

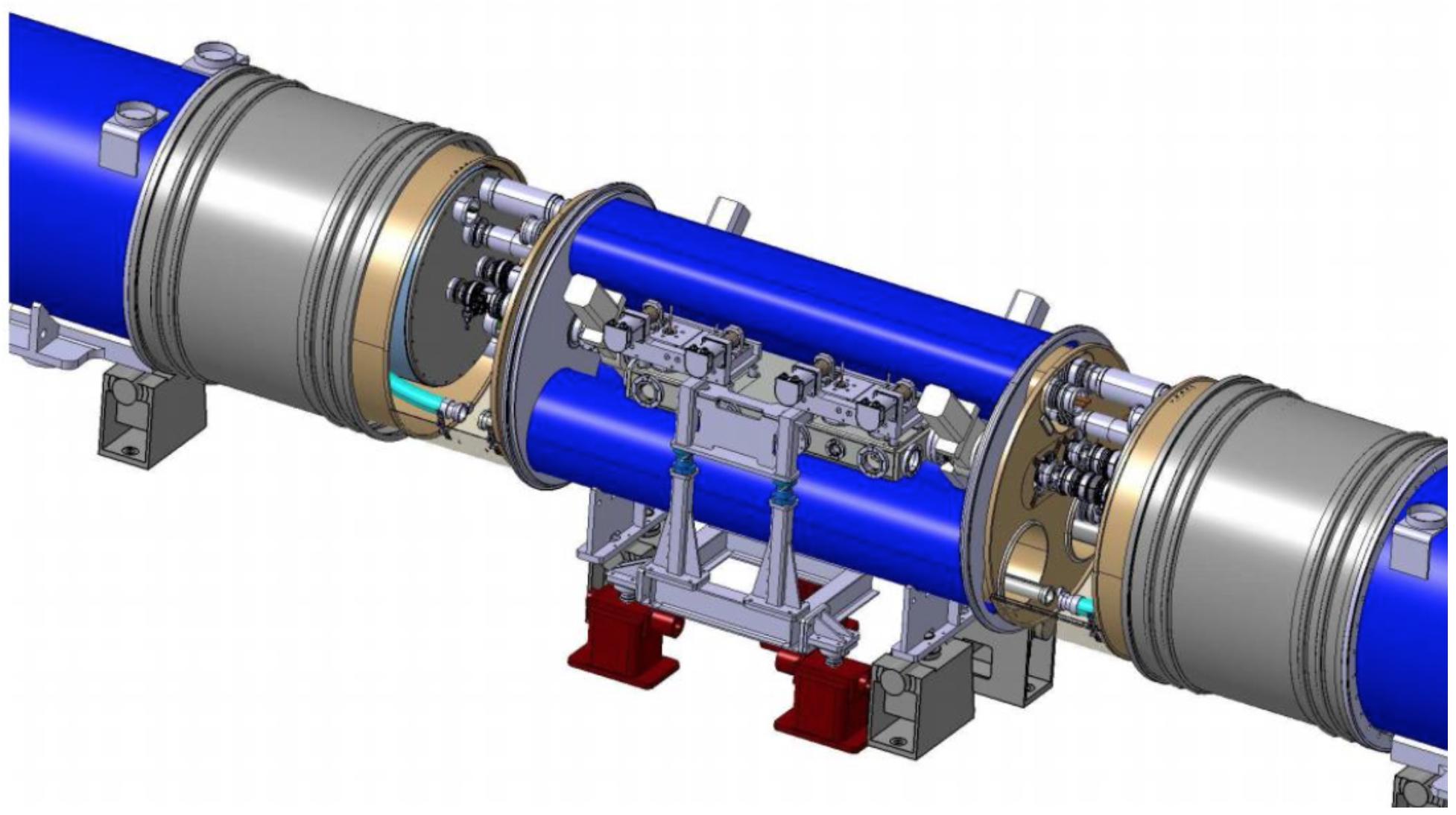

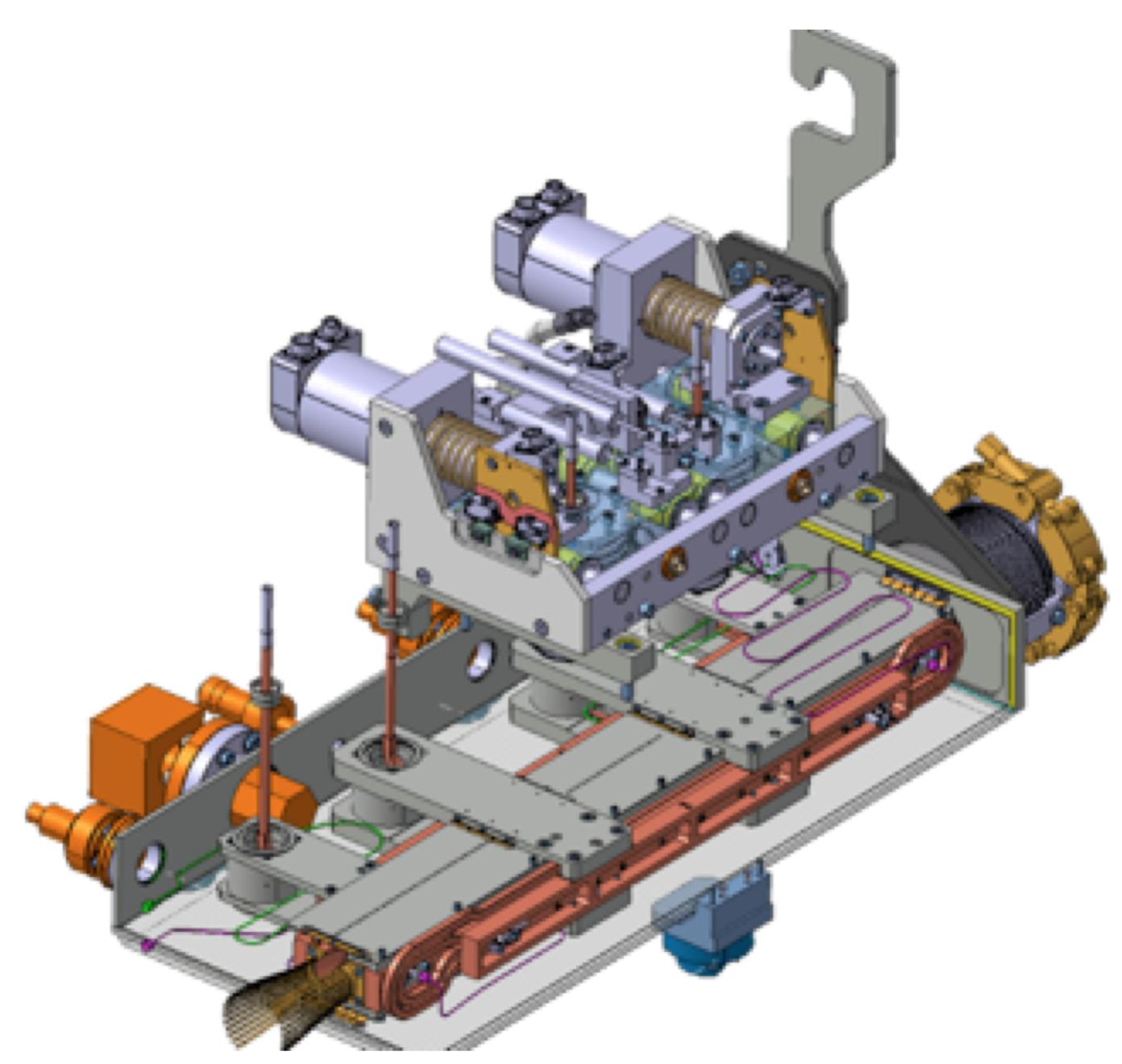

By summer 2017, a complete prototype of this collimator, which is referred to as TCLD, was built. It is shown in the figure above with a see-through cover. It was prepared for the companies that then participated to the tender for the production of these collimators (5 more units will be built and installed during LS2).